Shenzhen Fengyang Science and Technology Industry Co., Ltd.: Innovative solution for internal heavy-duty mobility of new energy storage container plants

Customer background:

A new energy electrochemical energy storage container production enterprise is committed to researching and producing high-quality electrochemical energy storage container business. In the early stages of factory construction, they realized the limitations of traditional transportation methods and contacted Shenzhen Fengyang Technology Industrial Co., Ltd. to seek innovative solutions to improve efficiency and reduce costs.

Challenges and Solutions:

The technical challenge of Fengyang Technology: Traditional transportation methods require high intensity factory structures, which have problems such as high cost, low efficiency, and ground damage. The customer requires the vehicle to meet the requirement of free movement of 40T/80T containers on site without laying steel rails.

Solution: Fengyang Technology's air cushion vehicle, as a heavy-duty transportation tool, has excellent load-bearing capacity and flexible maneuverability. Perfect fit to meet customer needs, the Fengyang Technology technical team has customized an air cushion vehicle heavy-duty mobile solution suitable for electrochemical energy storage container assembly production lines.

Air cushion vehicle mission:

Single air cushion vehicle transportation: Each air cushion vehicle can easily carry 20 foot container loads with a total weight not exceeding 40 tons for on-site transportation tasks.

Linkage transportation: Two air cushion vehicles are linked and controlled by a controller, capable of carrying 40 foot container loads with a total weight of 80 tons.

Functional advantages:

Through repeated demonstration and market selection of customers' functional requirements for air cushion vehicle product design, Fengyang Technology's solution stands out and brings many advantages to customers:

Cost savings: Compared to traditional wheeled transport vehicles, procurement costs are saved by over 40%, and usage costs are saved by over 50%.

Ground protection: The air cushion vehicle adopts omnidirectional ground movement function, continuously protecting the ground from damage and saving more than 50% of ground construction costs.

Improving efficiency: The efficient carrying capacity and flexible maneuverability of the air cushion vehicle significantly enhance the transportation efficiency of the production line.

Application scenarios

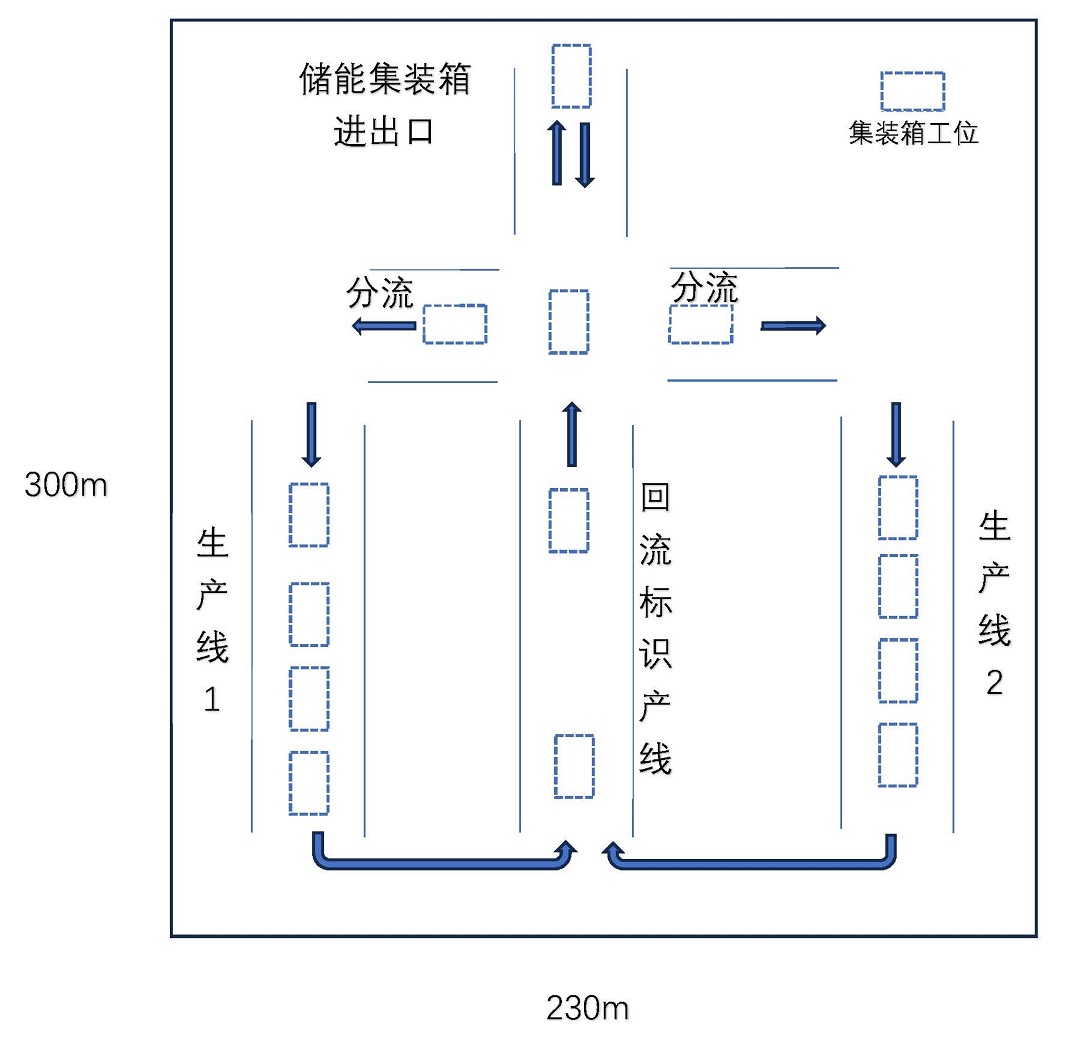

This case is the application of electrochemical energy storage container assembly production line. The entire process of moving tasks from empty containers entering the production line to complete assembly is carried out by air cushion vehicles. The movement route is shown in the following figure:

epilogue:

Fengyang Technology's air cushion vehicle provides customers with a new solution, helping them achieve the goal of efficient, convenient, and economical heavy-duty mobility within the factory. We will continue to uphold innovative concepts, provide customers with more high-quality products and services, and jointly promote the development of the new energy storage industry.